What is the PO Fruit & Vegetable Aid Scheme?

Producer organisations play a crucial role in the horticultural sector, especially in the growth of fruits and vegetables in the EU. There are approximately 2.2 million farms in the European Union dedicated to growing fruits and vegetables. These countries are amongst the leading producers in the world with European fruit and veg production valued at just under €70 billion.

Operated through Producer Organisations, the PO F&V Aid Scheme enables growers to apply for matched funding for eligible projects and investments - innovative technologies, infrastructure improvements and environmentally-conscious applications. The scheme’s structure offers growers the independence to allocate capital investments to where they will have the biggest impact. Growers contribute only 50% of project costs with the remaining amount match funded via Government Schemes. In the EU, there is a 7-year budget programme in place where POs are distributing funding of circa £1.5 billion through these schemes to growers. This financial assistance has advanced grower’s businesses by significantly increasing their overall yield and productivity.

In the EU fruit and vegetable sector, there are over 1,600 recognised producer organisations with Spain, Italy and France having the highest number in the sector.

What Are the Benefits of Producer Organisation Membership?

Producer Organisation memberships offer several benefits for growers, including:

• Overall better market position

• Strengthened collective power of farmers

• Knowledge exchange and technical assistance

• Better access to crop insurance

• Access to co-investment schemes (such as the PO Fruit & Vegetable Aid Scheme)

• Domestic growers’ risk being displaced by imports, undermining food security

Growers who fail to act on these compelling schemes may find themselves at a competitive disadvantage in the years ahead.

Maximise Efficiency, Minimise Investment

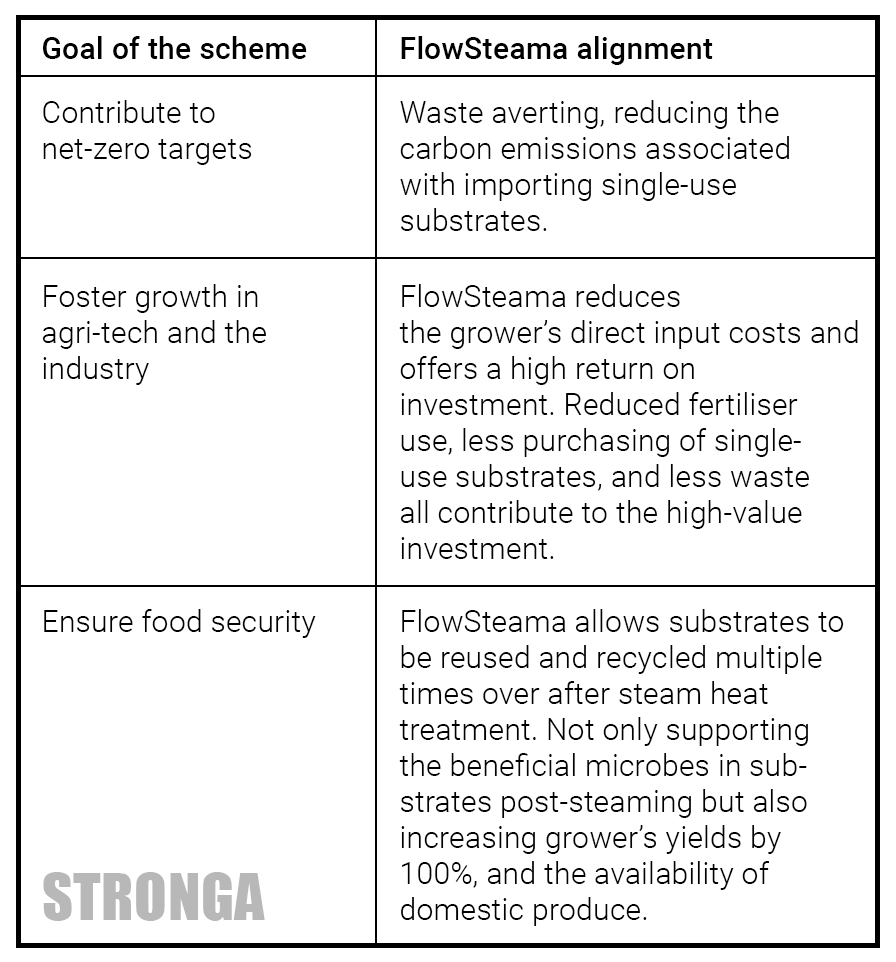

Stronga’s FlowSteama equipment aligns with the fundamentals of the EU F&V scheme, with the quality of growing substrate offering a significant influence on yield, productivity and quality of grown fruit and vegetable produce. Examples of FlowSteama’s steam pasteurisation benefits, in line with scheme compliance, are described in the table below.

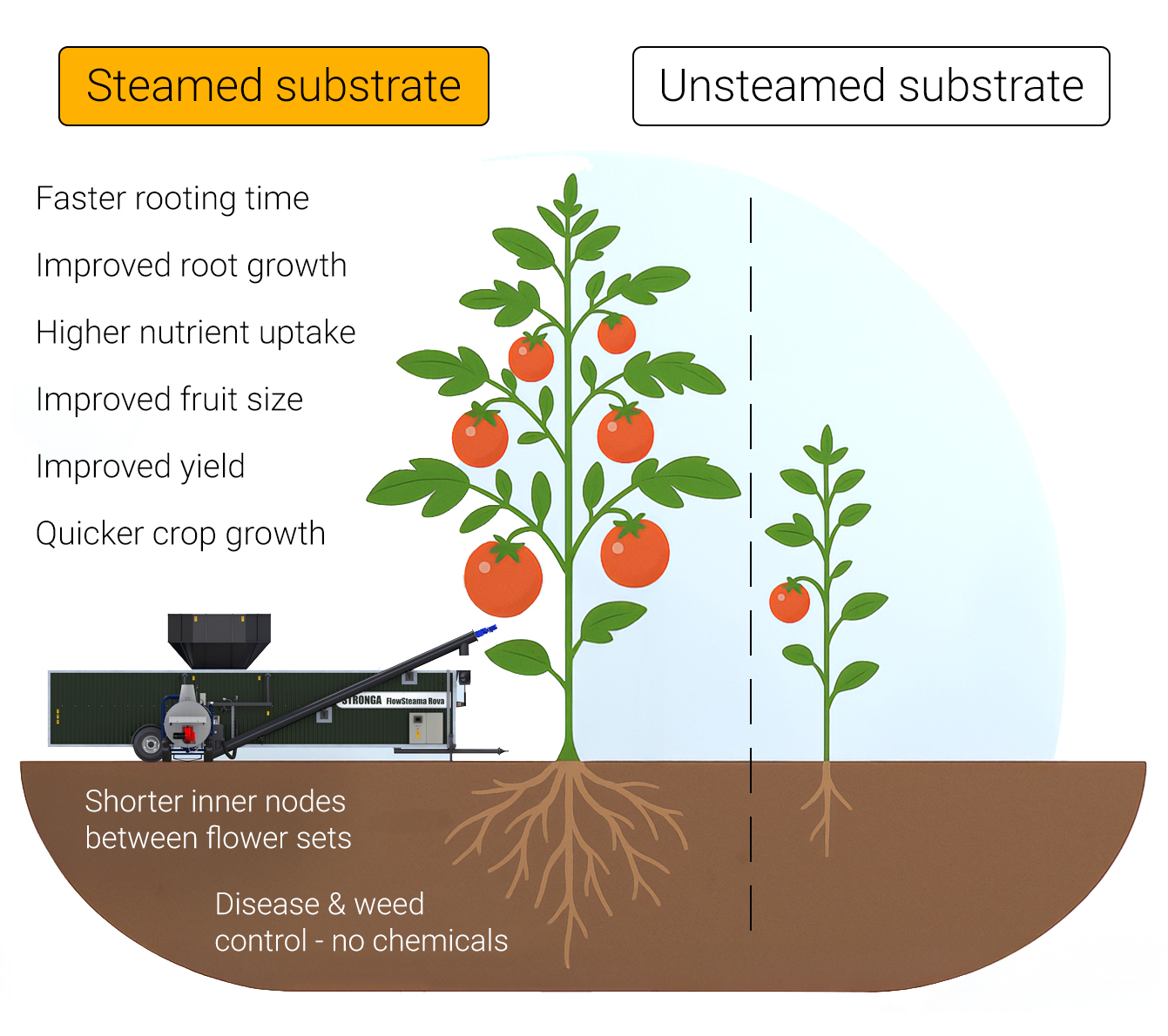

The animation below details the benefits of steam pasteurising growing substrates in greenhouses and plant nurseries. These benefits are covered in more detail further into this article.

What are the Benefits of Steaming Growing Substrates?

Proven Return on Investment

A number of growers have already secured funding for FlowSteama equipment, and are therefore already improving their bottom line through recycling growing substrates. Scaled and designed with the customer’s requirements in mind, FlowSteama equipment gives growers the ability to:

• Significantly increase yields; grower’s report 100% higher yields in steam-treated coir blend vs freshly imported coir.

• Lower carbon emissions and energy consumption associated with the importation of single-use substrates.

• Significantly reduce waste volumes through recycling spent substrates - recycling value.

• Reuse, preserve and revitalise growing substrates such as soil, compost and coco coir.

• Reduce transport costs associated with the importing single-use growing substrates.

• Lower growing media purchasing costs by reducing dependency on virgin material.

• Encourage longer fruiting seasons, leading to bigger fruits and healthier plants.

• Eliminate weeds, pests, and pathogens without using harmful chemicals.

• Improve crop hygiene and quality with certified pathogen-free media.

Turning Previous Purchases into Positive Gains

By steam pasteurising and recycling growing media, growers have the opportunity to reduce waste, improve efficiency and avoid fertiliser/pesticide use, thereby reducing the expenditure of purchasing virgin growing material.

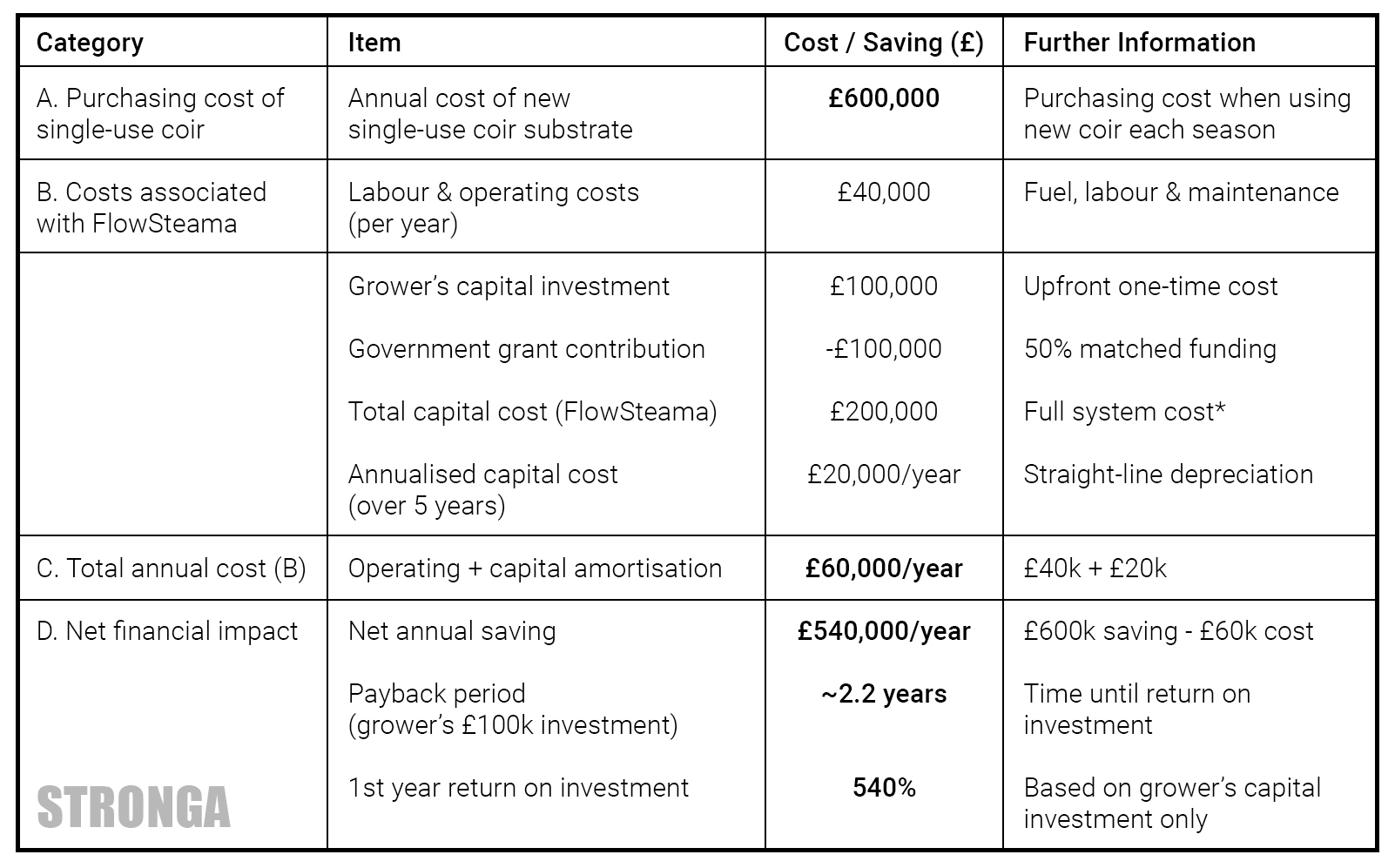

A number of FlowSteama owners have had proven success purchasing their equipment via funding schemes. In one case, a Stronga customer who had a large stockpile of spent coir enjoyed savings of £600,000/yr of the purchasing cost of virgin coir, using FlowSteama to recycle the material. The capital cost of the equipment was also match funded so the grower enjoyed a substantial ROI. The table below indicates the potential savings using FlowSteama compared to purchasing single-use, virgin substrates for each growing cycle.

*This table serves as an example. Costs may vary significantly depending on input material, system size, scale, capacity, automation and existing infrastructure.

What Makes FlowSteama Unique?

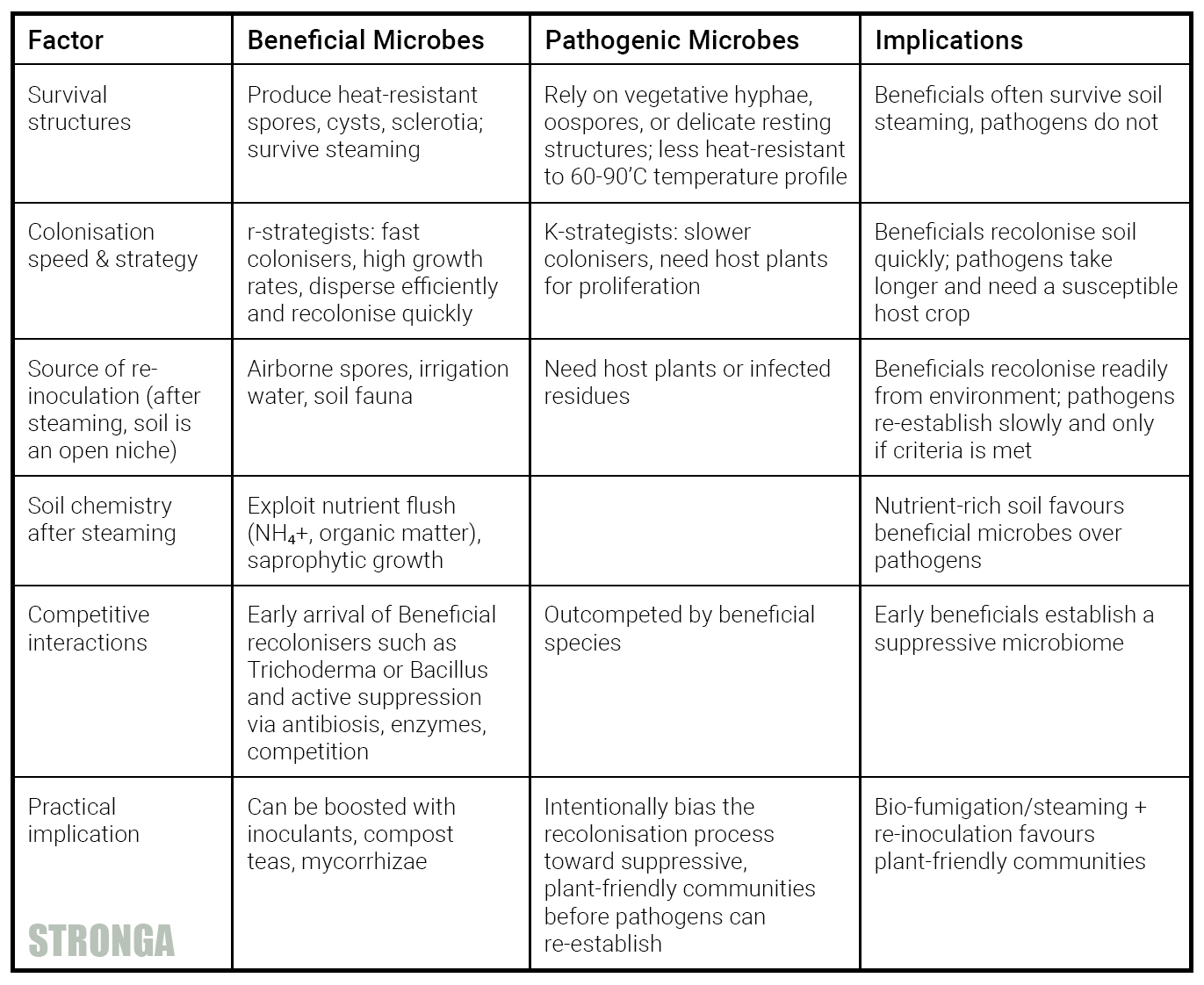

FlowSteama accepts super-heated 200’C steam which not only removes pests, bacteria and diseases from steamed growing material, but also unlocks nutrient availability, encouraging healthy roots of crops grown in the steamed material. FlowSteama can be configured to use on-site residual heat and uses low pressure dry steam, ensuring energy efficiency with minimal regulatory requirements.

FlowSteama’s unique PulseWave™ agitation motion ensures equal steam distribution across the entire load. What’s more, time at temperature controls, easily adjusted based on requirements, typically 30 minutes at 85’C, ensure that clients conform to local regulatory requirements for pasteurisation. The SteamStation™ HMI, which features unique sensor and logging controls, provides evidence-based process assurance. And there’s more; FlowSteama also offers:

Super-low operating costs ✓ Energy efficiency ✓ Improved sustainability ✓ Resource efficiency ✓ Lower production costs ✓ Reduced use of pesticides in production ✓ Increased control over substrate material ✓ Waste to wealth transformations, unlocking hidden value.

Overall, FlowSteama enhances the management of growing substrates, allowing growers to grow more with significantly lower single-use substrate costs. FlowSteama ensures growers can reuse spent substrate material, replace chemical sterilisation methods, enhance hygiene and reduce waste, contributing to improved environmental sustainability.

Let us help you uncover hidden value. Invest in research, innovation and match funded technology to help grow your business. Contact Stronga to find out more about the pasteurisation equipment; and let us support your funding applications – enquiries@stronga.com

Share this post