FlowDrya: Engineered for Drying & Phytosanitation

Bark is the interface between the tree and its environment so it provides the ideal vector for pests and disease. The impact of spreading invasive pests and diseases can be catastrophic, potentially destroying forests, ecosystems and even entire economies. Phytosanitation is, therefore, a legal requirement for businesses involved with transporting, importing or exporting bark around the world. Particularly in Europe, bark is now heavily regulated and international legislation is in place to reduce the risk of spreading pests and diseases across borders.

Engineered to meet heat-treatment standards, including critical phytosanitation requirements, while also drying bark to below 20% moisture content, FlowDrya transforms non-compliant, low value bark into added value product. This transformation creates reliable income streams for sawmills and other businesses needing to transport bark products overseas.

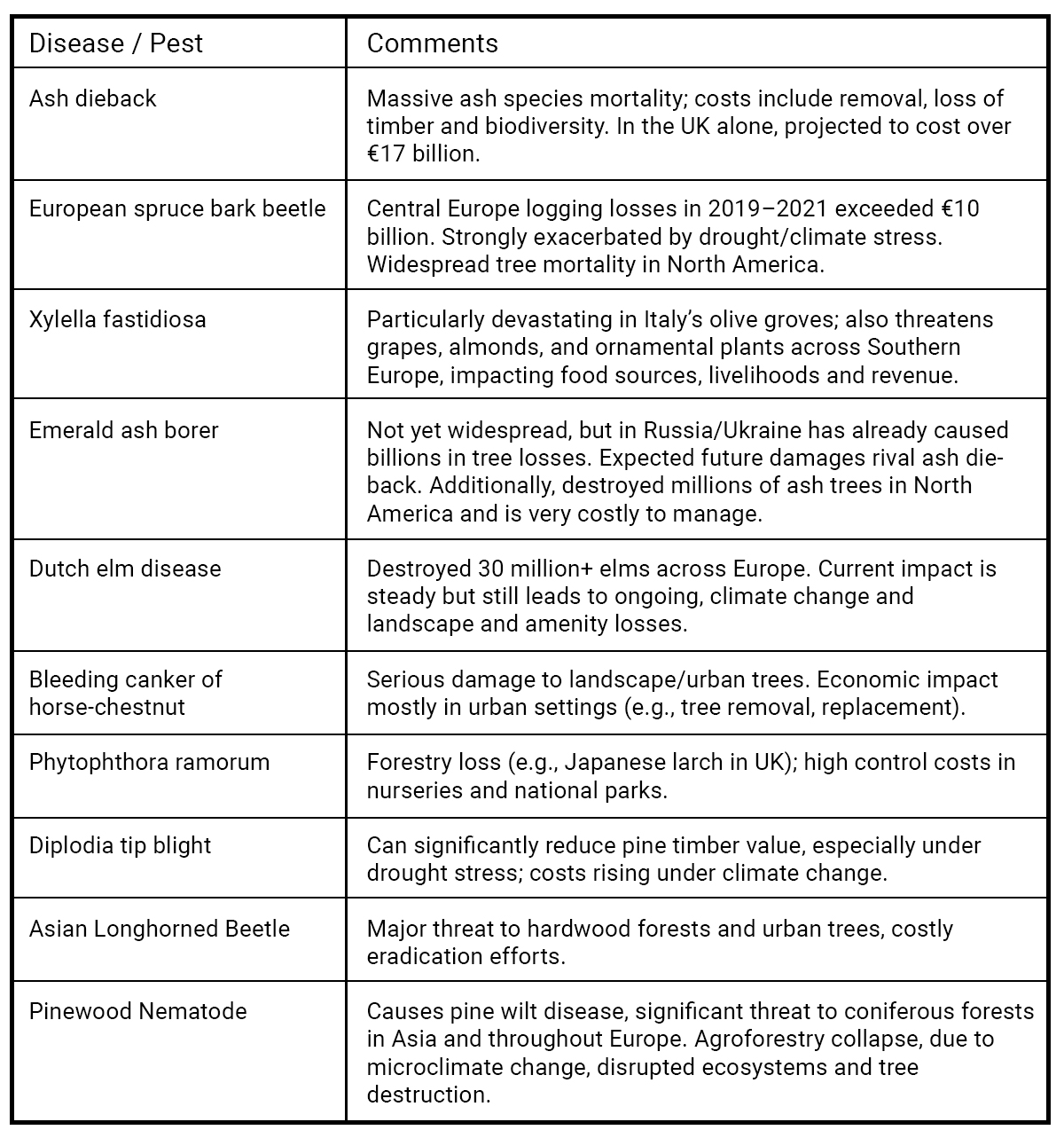

The table below shows some of the most harmful bark pests and diseases – reviewing their economic and ecological impacts.

Combined Moisture & Pathogen Removal

The official EU regulations listed on the UK’s Department for Environment, Food & Rural Affairs website, state that all companies handling bark residues must ensure their product has been heat-treated to a minimum temperature of 56’C for a minimum 30-minutes. Stronga’s equipment not only meets this standard but goes beyond, ensuring a measure of added security for suppliers. Once phytosanitation treatment has been completed, isolated bark can be imported by European countries as a high value, pathogen-free product.

FlowDrya or FlowSteama?

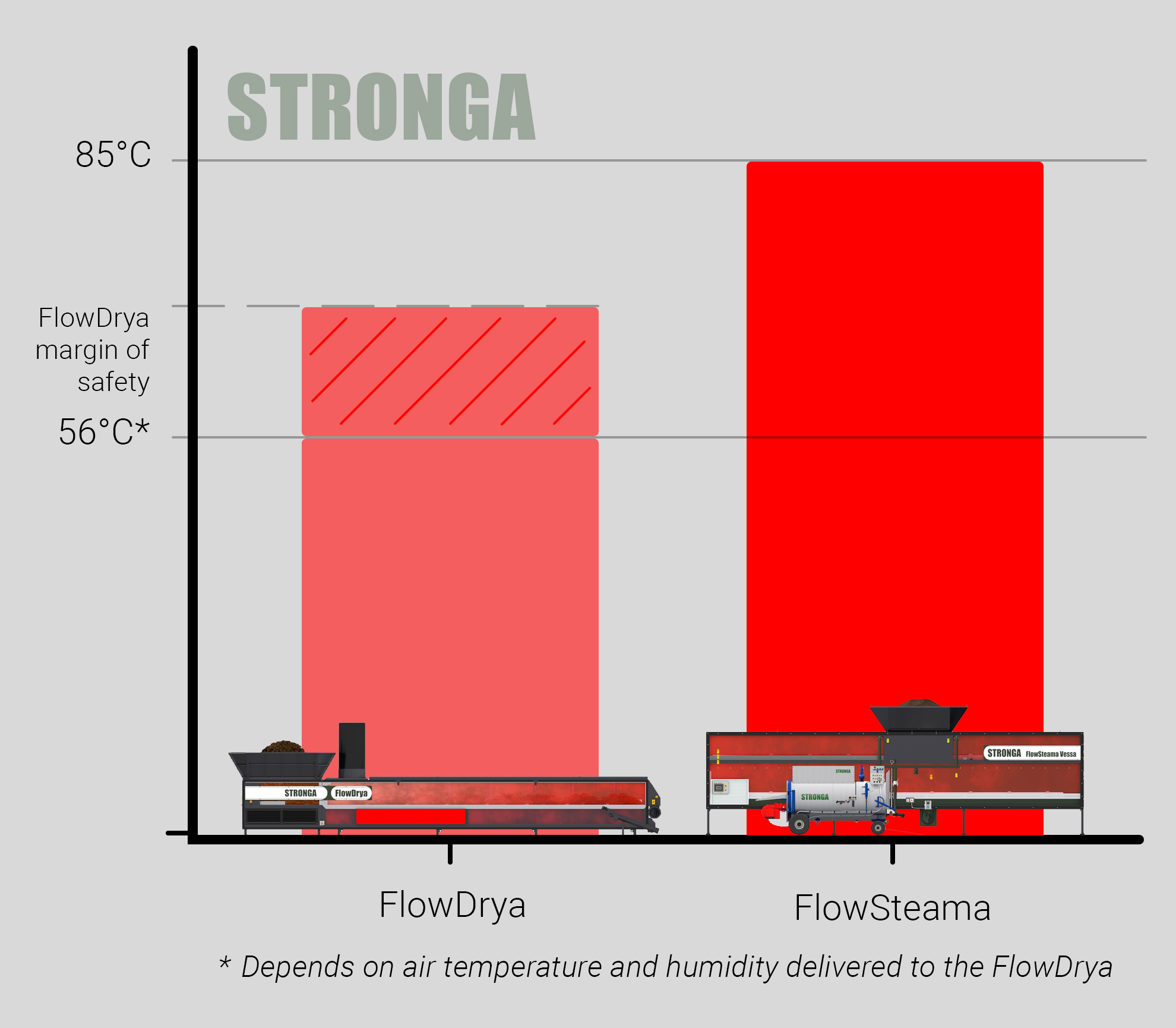

To ensure bark phytosanitation requirements are met for each specific tree species, it is important businesses refer to the official ‘National Plant Protection Organisation’ in the destination/source country or the ‘International Plant Protection Convention’. Higher phytosanitation temperature requirements may be better suited to FlowSteama, Stronga’s steam sterilisation solution, rather than the FlowDrya. Please discuss this with our team for more information. The chart below details the different heat- treatment capabilities of each machine, with a caveat in place for the FlowDrya.

Add Value with Phytosanitation-Approved FlowDrya Systems

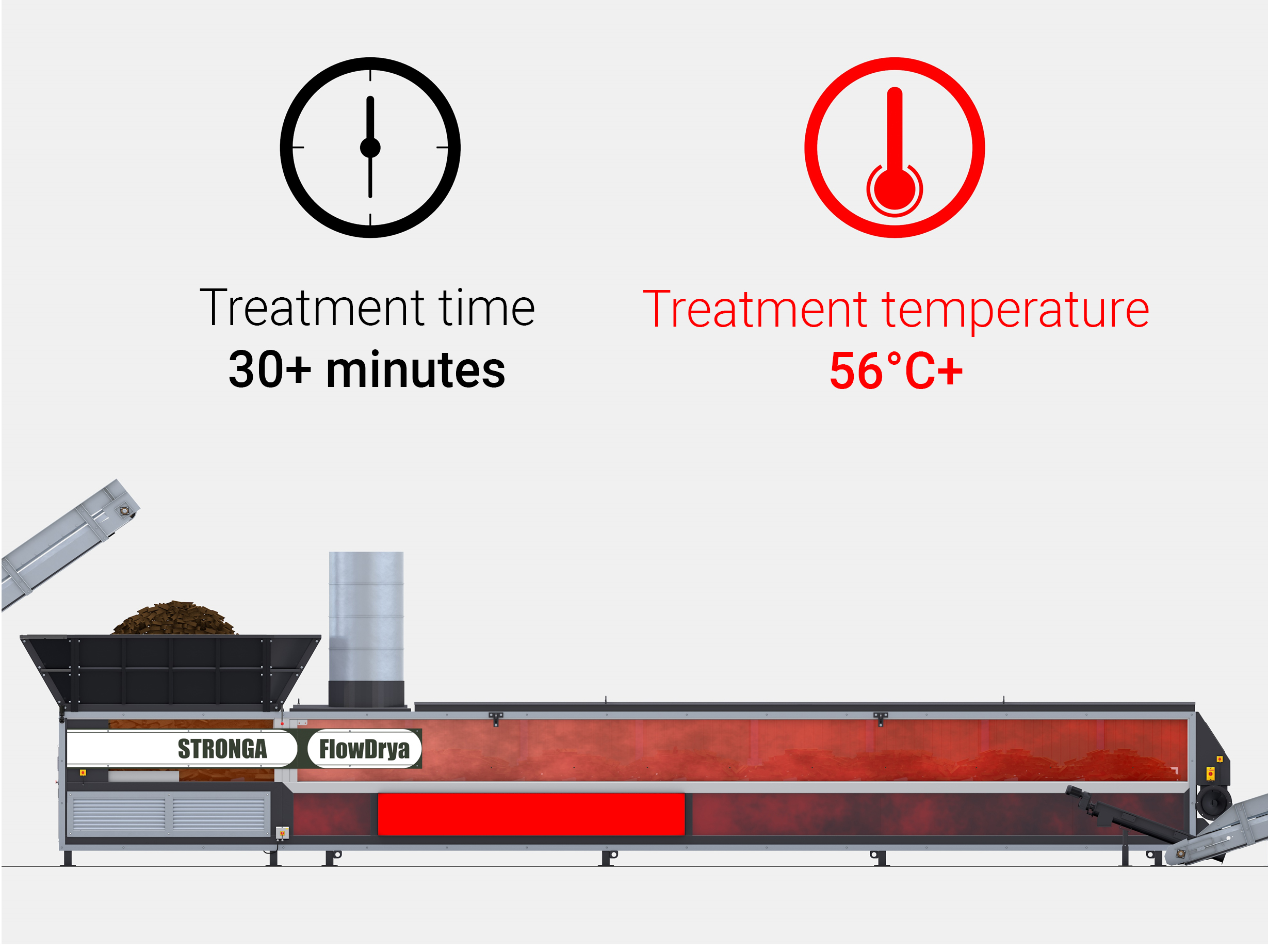

While bark products are growing in demand and are valued highly in the landscaping and gardening sectors, bark offers an especially high risk for transporting diseases across borders. Stronga’s FlowDrya equipment efficiently achieves time at temperature phytosanitation requirements of 30+ minutes at a minimum temperature of 56’C, as a heat treatment solution. In addition, operators can control the dry output from the FlowDrya, reducing the moisture content of bark down to their desired level.

The graphic below shows the capability of FlowDrya equipment in heat-treating bark.

FlowDrya equipment offeres multiple benefits, specifically for pathogen and moisture removal of bark:

• Fully compliant* with DEFRA’s phytosanitation legislation and trade standards, eliminating non-compliance rejection at the border.

• Export access to global markets, significantly extending overall profit potential.

• Moisture removal to below 20%, ensuring long-term stability and storage opportunities with reduced risk of mould or decomposition.

• One-step, combined phytosanitation and drying process, reducing the need for separate machinery, extra labour and extra handling costs.

• Drying improves the onward processing efficiency of bark.

• Drying bark significantly reduces the weight of the load (circa 50% lower bulk density), halving the transport costs and associated CO₂ emissions.

• Drying bark to below 20% moisture content enhances phytosanitation measures further by removing moisture from the storage environment, thereby eliminating the conditions in which pests and bacteria typically thrive.

* Please note that outside of Europe, other rules may apply. Please check country specific regulations. All compliance is subject to approval by the local certification authority.

Stronga: Pioneering Sustainability

Stronga are continuously innovating to provide practical solutions for evolving regulations and standards. FlowDrya’s dual-purpose heat treatment - drying solution exemplifies the need for ongoing development in line with regulatory requirements. Aligning our technology with the operational, climatic and regulatory requirements of our customers, Stronga ensures the upmost efficiency and compliance, aiding the reduction in environmental harm from the spread of non-compliant bark.

Discover the key operational benefits of FlowDrya:

• The unique PulseWave™ agitation system ensures consistent and even heat temperature profile, providing consistent heat treatment and drying across the entire load.

• DryStation™ HMI controls and data logging allow operators to target specific heat-treatment requirements, including phytosanitation requirements of 56’C+. This allows businesses to receive the certification needed for EU distribution.

• Simple, low maintenance design without belts, chains or sprockets, ensuring the highest operational efficiency.

• Semi-autonomous operation, keeping expensive labour requirements to a minimum.

• Optional integrated ElectraFlow™ using 100’C air, offering precise temperature control, faster heating and higher conversion rates of electricity to heat, which becomes especially efficient when paired with renewable energy or closed loop, on-site systems.

Not Your Ordinary FlowDrya

Sized to manage specific air flow temperatures while remaining modular and compact, FlowDrya equipment can be configured for dual bark phytosanitation and drying requirements.

Stronga adapt to your operational and compliance goals, giving you the flexibility to serve multiple purposes from a single machine. Contact our team today to begin configuring your pathogen and bark drying solution – enquires@stronga.com

Share this post