Berry Farming Built on Tradition & Commitment

Nestled in Kent, the ‘Garden of England’, Hugh Lowe Farms have a rich family heritage and long tradition of growing the freshest, best-tasting strawberries, raspberries and blackberries. With over 125 years’ worth of experience, they are widely recognised for their industry-leading practices and positive contribution to the environment. Their annual, 25-year appointment as lead supplier of strawberries to the prestigious Wimbledon Championships is testament to their dedication of consistent quality and one reason why they are considered exemplary in their field.

The family-run business was founded in 1893 by Bernard Champion on the principal importance of positive, ongoing development, always serving and protecting future generations. Now, decades later, the farm has maintained this fundamental value by pioneering technological advances that keep nature at the forefront of their work. Learn how Stronga’s collaboration with Hugh Lowe Farms has enabled them to recycle and reuse the coco coir media used to grow their delicious berries.

‘Net Zero Pledge’ in Berry Growing

As one of the largest berry farms in the UK, with over 700 hectares of land and an annual production of over 6,000 tonnes of berries, Hugh Lowe Farms are aware of their significant responsibility to both the local environment and people. The farm aims to contribute positively to their ‘net zero pledge’ through actively reducing their greenhouse gas (GHG) emissions. A key element of this commitment to the environment was a project they have undertaken, focussing on recycling and reusing their coco coir growing media.

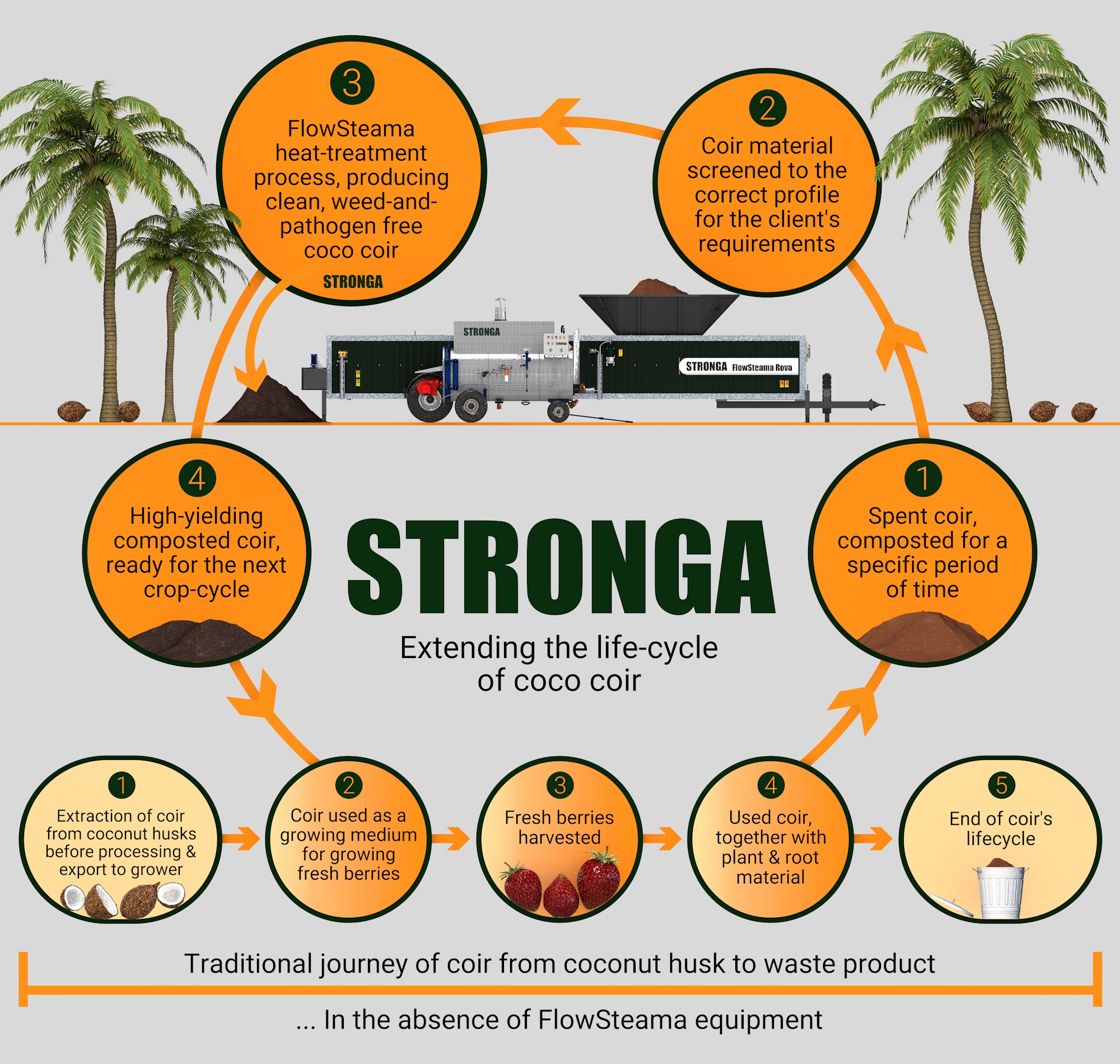

The graphic below compares Hugh Lowe Farm’s new, circular, recycling process (darker yellow) against a wasteful, single-use coir process (light yellow). Read on to learn more about Stronga’s involvement on this important, long-term endeavour.

Coco Coir Recycling – The Future of Sustainable Growing

Peatland perseveration has become a critical topic in discussions around carbon, climate change and biodiversity. Fast-approaching regulation deadlines have increased pressures on growers who have been forced to source suitable alternative growing materials. Hugh Lowe Farms were ahead of the game and stopped using peat in their business around 15 years ago. Their chosen alternative, coco coir, has proven an excellent peat-free growing medium with its excellent versatility and sustainable origin.

Fast forward to 2024; the farm has continued their dedication to sustainable growing, clearly recognising the financial and carbon costs associated with importing single/dual-use coir from the other side of the world. Stronga FlowSteama equipment has enabled the farm to recycle coir for use multiple times over, aligning with their principles of environmental stewardship with preservation of natural, organic resources.

Steaming Ahead – The Coco Coir Sterilisation Process

Learn Hugh Lowe Farms’ new coco coir sterilisation process, using FlowSteama equipment.

1. ‘Spent’ coir material is removed from polytunnels at the end of each growing cycle and then stockpiled and composted over a period of time.

2. Mobile FlowSteama equipment is moved to each stockpile so the spent material can be adequately steam heat treated.

3. After a cooling period, the rejuvenated material is available for the propagation of strawberry plants or the next crop and will also be recycled for use as potting compost or to improve soil structure and fertility of land.

FlowSteama offers a continuous loop cycle where coco coir can be steamed, recycled and reused multiple times over.

The Benefits of Steam-Treating Coco Coir

- FlowSteama reduces the need to purchase virgin coir for each cycle, allowing farmers to respect precious resources.

- FlowSteama increases the grower’s control of material, reducing the risk of shipping delays and uncertainty around shipping fees and coir costs, while also removing any ambiguity surrounding the coir’s provenance.

- FlowSteama allows for cleaner growing substrate in comparison to non-steam treated coir, reducing the risks of specific strawberry pests, spotted wing dysphoria and plant parasitic nematodes.

- Steam sterilising coco coir substrate allows for stronger and healthier plants. Research suggests crops grown in steamed, composted coir have shorter inner nodes between flower sets, allowing for increased flower growth opportunities and higher berry yields.

- One batch of steamed coir delivers more fruit cycles and longer picking seasons. There is evidence that a suitable composting period followed by steam heat treatment can double the output of crop per litre of coir.

- The super-heated steam process unlocks nutrient availability which encourages healthy berry roots of crops grown in the steamed material. Strawberries grown in steam treated, composted coir have excellent qualities in terms of appearance, juiciness and taste, even better than those grown in single/dual-use coir.

- Steam treated, recycled coir can retain up to 11X its weight in moisture, delivering healthier, more robust crops.

Revolutionised Growing Process

Adopting regenerative techniques has enabled Hugh Lowe Farms to reduce their GHG emissions and make significant progress towards their net zero goals. Steam sterilisation is a highly efficient and effective, chemical-free method of recycling spent coir, ensuring crops grown from sterilised coir are free from organisms pathogenic to strawberry plants, which can lead to disease.

Revitalised coir fibres, rich in carbon, can also be used to enhance soil. As an example, Hugh Lowe Farms use their recycled coir on their arable fields and as potting compost for establishing further crop cycles. Their mindful approach to recycling, using organic steam, extends the life of coco coir and extracts all potential value from the material. Investing in FlowSteama equipment has enabled them to become a resilient and reputable leader in resource recovery.

Grants Available for GHG-Reducing Farms

As an added incentive for growers to make the smart investment in Stronga’s steam heat treatment solutions, there are beneficial grants available to help farms reduce GHG emissions. Providing you can demonstrate how FlowSteama equipment improves your onsite productivity and delivers environmental benefits associated with its use – you could be eligible.

The UK’s ‘Improving Farm Productivity Grant’ is one example, available for those who are using advanced technology to improve efficiency, resilience and sustainability in farming operations. In Hugh Lowe Farms’ case, recycling coir via FlowSteama allows for a 100% increase in crop output per litre of coir, whilst contributing positively to GHG reductions and enhanced management of land, soil health and coir resource. Coco coir is reused, which reduces the emissions associated with continuously purchasing single/dual-use substrate, and carbon present in coir fibres remain in the soil and enhance the land – a win-win situation.

In an attempt to increase existing carbon stores in soil and reduce emissions from soil, the UK government have published the ‘Safeguarding our Soils’ strategy which outlined that ‘protecting and enhancing stores of soil carbon’ is key to reaching emission reduction targets.

Stronga ‘YieldBoosta™’ is Transforming the Growing Industry

Food growers are under immense pressure to ensure their grown berries align with stringent food security and consumer demand regulations. What’s more, there are also increased pressures to evidence CO₂ emission reductions, including the often-hidden shipping emissions. FlowSteama’s technology enables carbon reducing practises.

FlowSteama’s yield-boosting technology is suitably scaled to the customer’s individual requirements and variables (material type and more). Guaranteeing material temperatures over 85’C, FlowSteama’s super-heated steam system certifies that harmful pests, pathogens and diseases are removed from coir, alleviating some of the pressures on growers. The SteamBoila can also be used to steam grower’s pots and trays between cycles, allowing for more accurate phytosanitation than manual spraying, cutting operating and labouring costs dramatically.

FlowSteama: A Vital Cog in Carbon-Reduction

- FlowSteama slashes operating costs, lowers carbon use and reduces CO₂ emissions.

- FlowSteama enables a more transparent method of calculating carbon savings and fuel consumption.

- FlowSteama is fully insulated and energy efficient. As coir is such a low-density material, it requires even less energy to steam sterilise, up to 6X less than soil.

- The PulseWave™ motion, FlowSteama’s highly effective material agitation system, removes any lumps in the load, allowing super-heated steam to penetrate the coir more effectively.

- SteamStation™ HMI controls provide evidence and assurance that core time-at-temperature has been achieved and that all pests, fungus, diseases and pathogens have been eradicated from the coco coir. All records are kept for up to a year to prove required parameters have been met.

- Compact, modular and mobile, FlowSteama can be seamlessly integrated into workflows, boosting coir productivity.

FlowSteama adds value. With over 25 years of experience in the industry – we provide clarity, speak to our friendly team today: info@stronga.co.uk

Share this post