Biochar has long been recognised as a transformative resource for amending soil and improving land management, offering big benefits such as enhanced soil fertility, improved water retention, and excellent carbon sequestration. It’s simple, one-time application offers significant potential for sustainable agriculture and climate change mitigation, reducing the nitrous oxide and methane released from soil and the volume of carbon released into the atmosphere.

The potential of biochar is HUGE.

At Stronga, we realise that the effectiveness of biochar is closely linked to its quality, which can vary depending on the chosen production method. One critical step in optimising biochar properties is the drying of the selected biomass feedstock, prior to pyrolysis.

Adequate drying not only improves the efficiency of the pyrolysis reactor process but also enhances the structural and chemical characteristics of the resulting biochar, ultimately maximising its overall environmental benefits. Learn more.

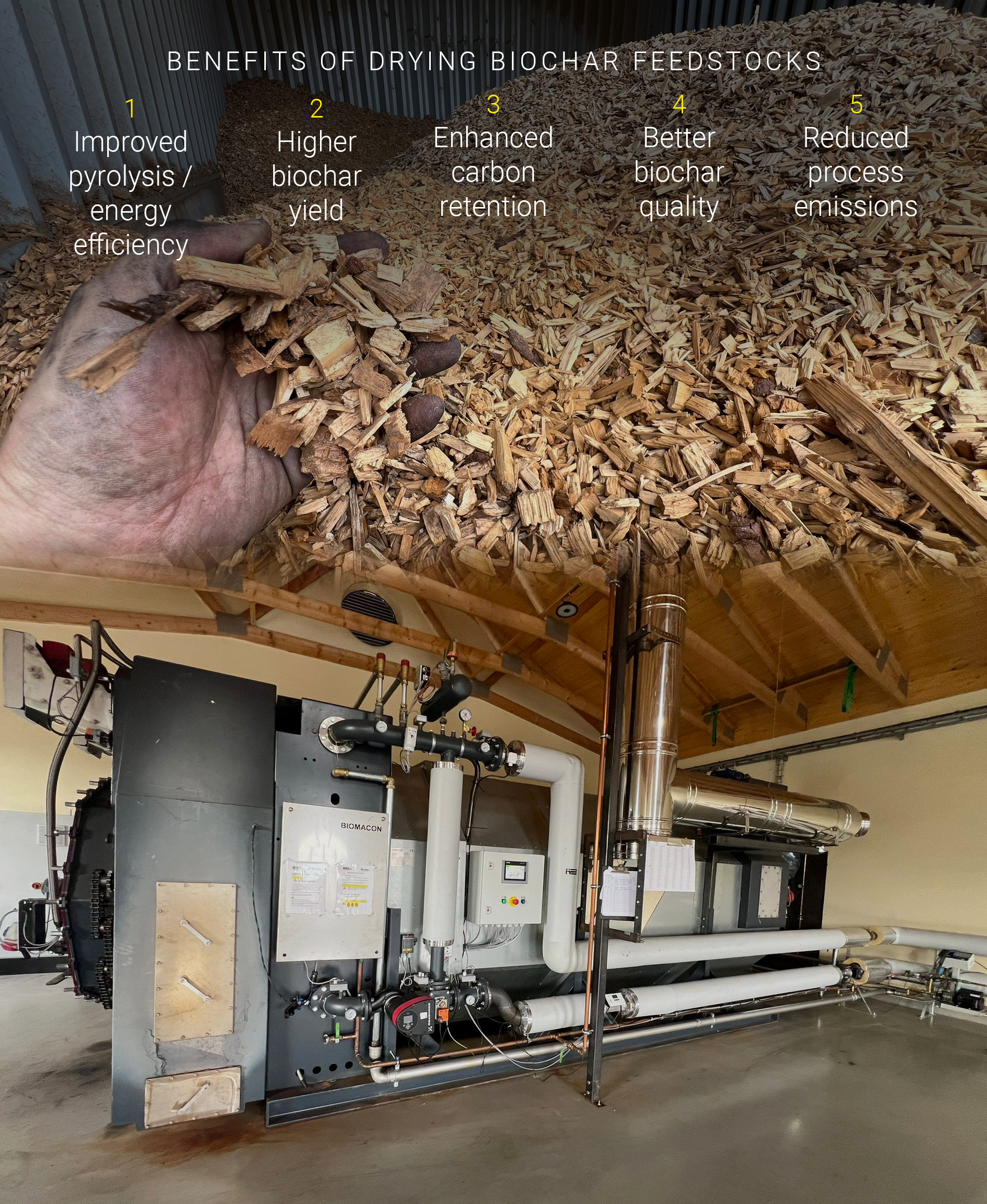

Top 10 Benefits of Drying Biomass Feedstocks

1. Improved pyrolysis / energy efficiency – delivering dry feedstock into the pyrolysis chamber reduces operating costs and residency times. This means, in the reactor, higher temperatures are achieved faster, allowing for complete carbonisation of feedstock and a higher thermal output.

2. Higher biochar yield – FlowDrya directly increases biochar yield, increasing the proportion of biomass that is able to be converted into biochar by removing the excess moisture in the feedstock.

3. Enhanced carbon retention – dry feedstocks enable stable carbon formation while minimising carbon losses to volatile compounds.

4. Better biochar quality – drying enables the production of better-quality biochar with more consistent porosity, surface area and carbon structure.

5. Reduced process emissions – lower moisture biomass decreases the CO₂, CO and methane emissions from inefficient combustion of pyrolysis gases. Inputting dry feedstock into the pyrolysis chamber minimises steam produced, VOCs and tars - all of which contribute to air pollution.

Continued…

6. Stable thermal profile – dry biomass allows for better control over temperature in the reactor, heating rates and residency times.

7. Lower operational costs – less energy is wasted evaporating water, reducing fuel and electricity requirements associated with the pyrolysis process.

8. Minimised tar, condensate formation – dry feedstock reduces the formation of problematic condensable volatiles.

9. Improved reactor throughput – faster heating and carbonisation of dry biomass directly increases production rates. The lifespan of reactor equipment is also improved. Drier biomass minimises clogging, rust and corrosion of components.

10. Reduced storage and handling issues – dry biomass is less prone to microbial degradation, mould growth and spontaneous heating whilst in storage.

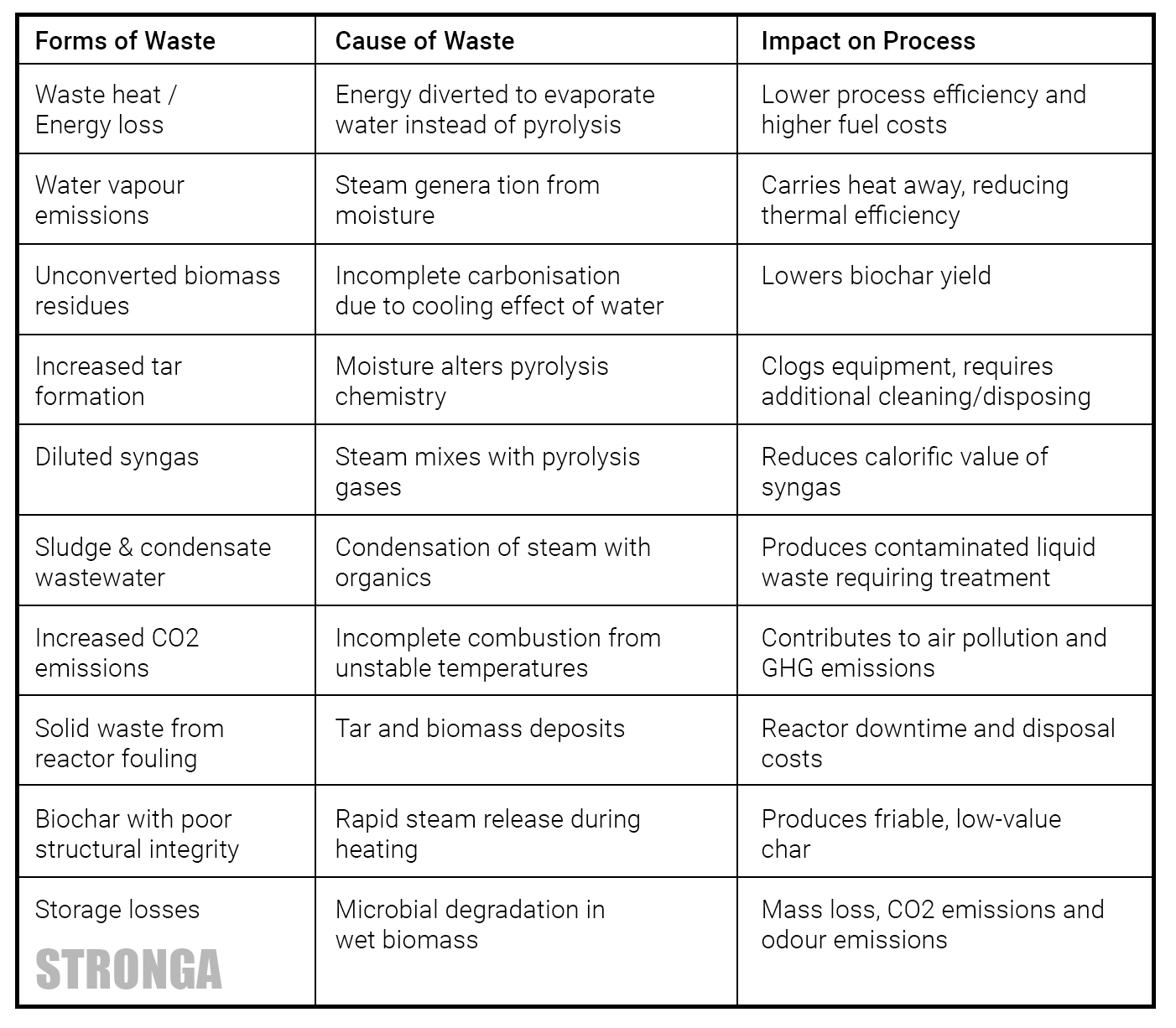

What are the effects of using high moisture biomass in biochar production?

The table below summarises the main forms of waste caused from inputting wet feedstock into the pyrolysis chamber, together with their significant effects.

Dry Feedstock Improves Biochar Quality & Consistency

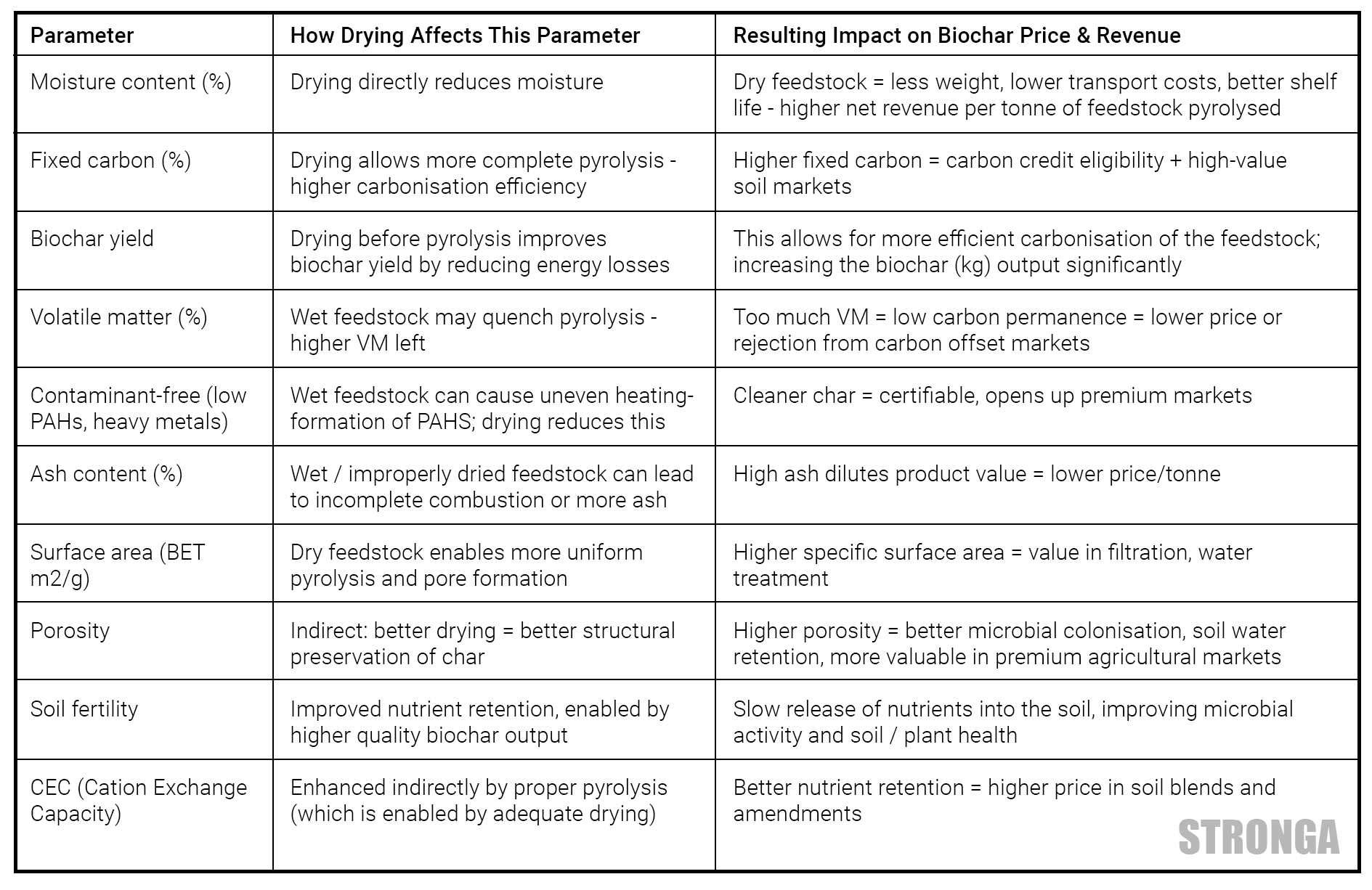

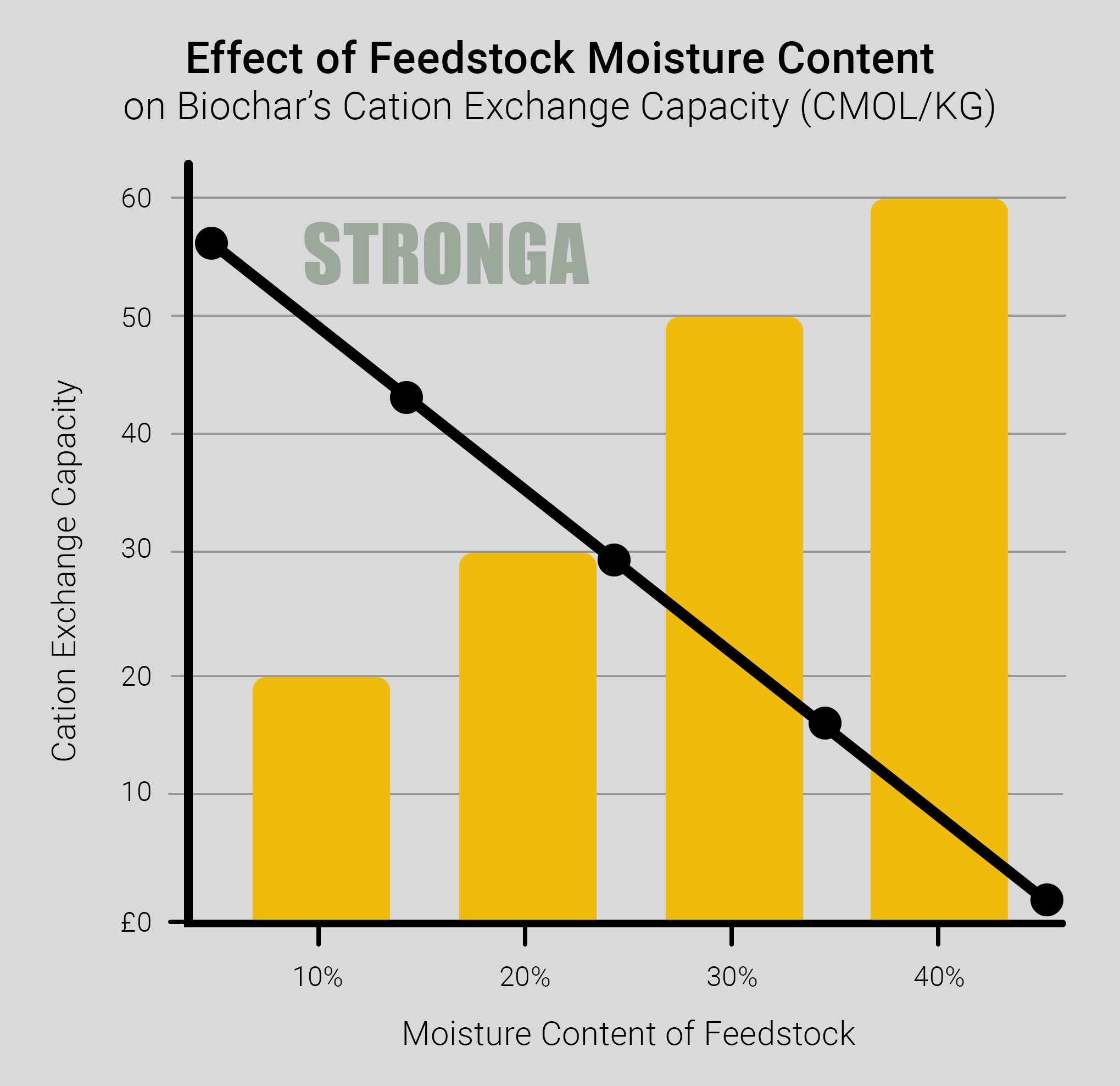

High moisture content feedstock = low carbon content biochar. Dry feedstock delivers:

• Higher fixed carbon content and stability, ensuring effective long-term soil improvement and carbon sequestration.

• Increased biochar yield per unit mass of feedstock, allowing for higher carbon percentages in the biochar output.

• Better biochar quality with a higher fixed carbon content. Less moisture leads to more complete pyrolysis, higher fixed carbon content and lower volatile matter in the final product.

• Higher surface area and porosity, improves microbial colonisation and nutrient retention. Improved porosity also improves water absorption rates in the soil.

Watch Stronga’s biochar feedstock drying video below.

The Effect of Drying on Biochar Profitability

FlowDrya; A Master in Moisture Removal

Understanding the importance of adequate moisture removal in biochar production is vital. Stronga’s FlowDrya is a master in moisture removal. See below a summary of the unique features of the dryer, or reach out to the Stronga team for more information.

• FlowDrya equipment is modular and scalable to suit the customer’s requirements. The Stronga team consider location, feedstock and throughput requirements to ensure each dryer best reflects each unique operation.

• The design of the FlowDrya is simple and low maintenance without belts, chains and sprockets, ensuring the highest long-term operational efficiency.

• Semi-autonomous, minimising increasingly expensive labour requirements.

• Unique PulseWave™ agitation motion (shown below) ensures a consistent and even heat profile across the entire biomass load.

Elevate Your Process

Contact Stronga today to learn how FlowDrya equipment can take your biochar production process to the next level. Efficient drying means better biochar quality, higher yields, and healthier soils; don’t delay getting in touch - enquries@stronga.com

Share this post