At Stronga we have been talking to CBD oil extractors about the key elements which add value to industrial hemp crop processing for CBD oil extraction. They confirmed one of the most important things when it comes to selling your hemp crop after the potency and the CBD oil content is the dryness of the material.

So when CBD oil extractors are looking for material, it must be dry. When extractors get material that is wet in the bag it will only last a few days at most. All hemp processors require the hemp to be fully dried to ensure the material is stable during transport and storage before CBD extraction.

Protecting CBD Content

Several types of hemp drying solution are available; however there is a common danger in drying. Some drying processes will damage the CBD content in the end product. Typically this damage happens when the drying process is too hot.

Stronga FlowDrya and Heatex hemp drying solutions are designed to be low temperature, allowing accurate control of the drying temperature below 150˚F (68˚C). Often clients are choosing to dry below 120˚F (49˚C). The limit of drying temperature avoids the risk of damage that high temperature drying poses to the CBD oil chemistry and direct links to price and profitability of the hemp crop.

Hemp-Temp

This “temperature of hemp material” aspect is complicated by the temperature rise of material during the drying process. Wet hemp input biomass often starts close to ambient air temperature with hemp material temperature rising during the drying process towards the drying air temperature (depending on some factors).

Airflow Consideration

Airflow is another key factor to consider when drying industrial hemp crops. Some drying processes use fast airflows which shatter the delicate, high value, high CBD oil content. These fast airflow dryers carry hemp through and out the dryer along with the wet exhaust air. Precious CBD trichomes (crystallized oil) are lost; these dryer literally blow your money away.

Separation of valuable hemp leaf material from wet exhaust air is not an easy process; most cyclone systems do not work well in high humidity air off separation situations.

Dry Hemp = Added Quality & Profit for the Grower

Any processor wants an easy transaction with a grower, meaning a dry, stable hemp product. Dry hemp will make for an easier, more valuable sale of industrial hemp crop to a CBD oil extractor.

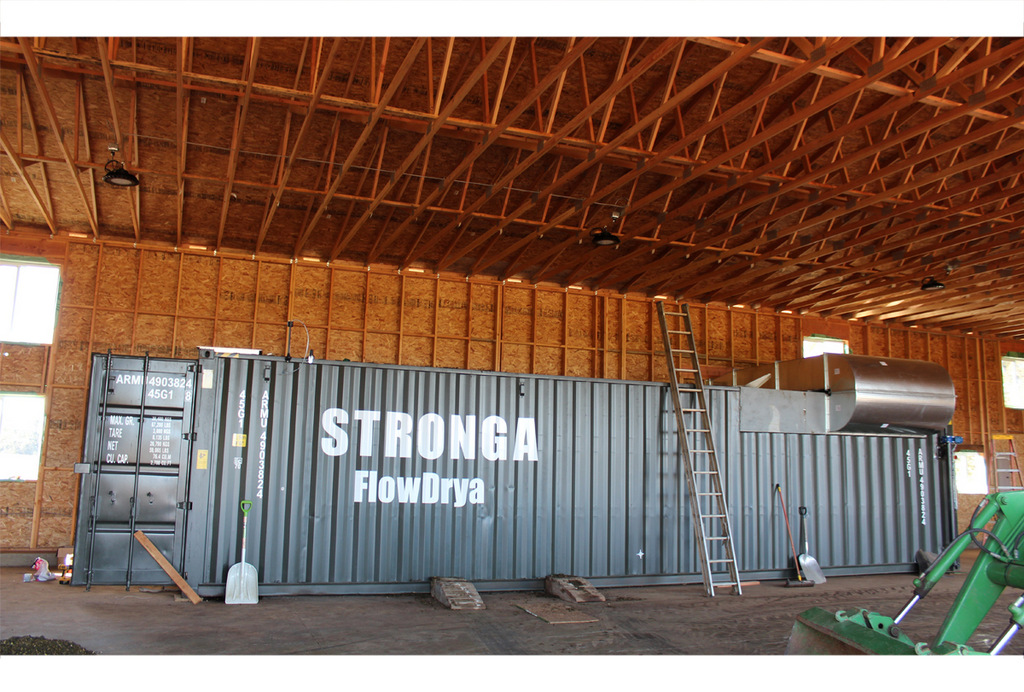

Stronga FlowDrya Benefits in Drying Industrial Hemp

FlowDrya has a number of benefits for hemp CBD oil extraction over other drying systems:

1. FlowDrya is purpose designed as a low temperature, wet biomass dryer (not adapted from high temperature grain drying for example);

2. FlowDrya is gentle on the hemp plant with a slow moving PulseWave™ motion down the drying bed, minimising leaf shatter while gently lifting and mixing the material to optimise drying efficiency;

3. FlowDrya features an under-plenum to collect any valuable CBD-rich leaf or flower parts which drop down in the drying process. These are augured out dry into a suitable bag;

4. PulseWave™ reduces air pressure, thus making the airflow gentle on the hemp plant, minimising dust and risk of light hemp leaves being blown away from the dryer.

5. FlowDrya has no belts, shafts, chains or sprockets for hemp fibres to wrap on (hemp loves to wrap on shafts and bearings). This leads to high reliability drying;

6. Optimised airflow reduces air speed in the dryer, minimises risk of “blown off” losses together with those precious trichomes;

7. Overall optimised efficiency and control of the hemp drying process via Stronga hemp biomass drying solutions.

Effects of Harvest Method on Drying Speed, Time & Energy

The choice of hemp harvest method, together with any green pre-drying process such as hemp plant stalk removal, de-bucking or wet trimming will affect the total drying speed.

Increased wet biomass to dry occurs when hemp stems / stalks are included in the drying material. This means the total amount of moisture to be removed is increased; this is a key factor in considerations for field-scale industrial hemp production

Hemp stems are tough, fibrous and long. Generally the moisture needs to be extracted down the cell wall which is slow process. Hemp stalk material has a dense outer layer which is resistant to high speed moisture extraction through the stem wall or epidermis.

Effect of Field-Scale Hemp Growing Strategy on Total Biomass to be Dried

As discussed in previous articles, there are many factors affecting the total volume and type of hemp biomass per acre / hectare.

The hemp variety, planting spacing strategy, fertilising strategy, soil types, seasonal and weather factors will all combine to affect the total hemp biomass.

Balancing Manual Industrial Hemp Harvest - Labour

Wet trimming, either fully manually or semi mechanised destalking / debucking is a labour intensive process and hard to automate to field-scale industrial hemp growing operations.

Some hemp growers choose a two-step drying process where whole or trimmed wet hemp plants are dried down to a selected moisture level, then the stalks are separated in mechanical processing from the leaves, flowers, buds and higher CBD content material.

Green Whole Crop Hemp Chopping Option – Moving to Field-Scale Production

Evenly chopped green hemp will generally increase the drying speed over longer stemmed hemp drying.

Shorter stalk sections and more homogenous biomass size speeds up drying and enables more even drying, even though the density of the stalk biomass varies from that of the leaf. This flower and bud are also dense and hold moisture longer than the leaf.

There are clear benefits of hemp forage harvesting with correct equipment to bring more uniform biomass to the drying process and assist in managing harvest speed in good conditions.

However there are also studies showing that CBD trichomes are shattered by rough forage chopping and handling with CBD oil volatiles realised in the harvest process reducing the CBD oil content leading to significant losses of value.

The way forward towards optimisation of profit from CBD oil extraction industrial hemp crops seems to indicate gentle handling of the crop.

Simple & Practical Solutions for the Grower with FlowDrya

No matter the harvest method you are planning or the field-scale you are developing, a correctly-scaled FlowDrya system can help you can optimise dry output in the vital hemp harvest window.

Call the Stronga sales team today for assistance in hemp dryer product and model selection.

Email info@stronga.co.uk or call 01992 519000.

Share this post